JKS and HJKS Vortex Pumps

Very wide passing long shaft sewage, sediment and waste water pumps

Very wide passing JKS and HJKS vortex pumps are suitable for sewage, sediment and wastewater pumps. Rubber lined or with another surface treatment the pumps withstand very hard and abrasive use.

Our wide passing and long shaft vortex pumps are suitable for many purposes. These pumps are versatile can be used to pump and move for example sewage and different industrial sediments. Also many particles containing heavy masses can be

pumped without shredding and crushing.

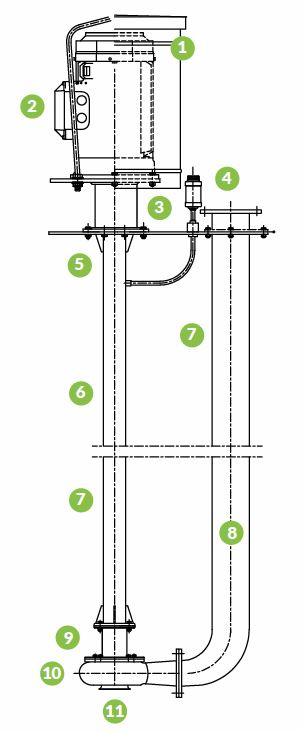

The JKS and HJKS vortex pumps have an impeller that enables a strong vortex. It sucks in everything that can fit in through the intake manifold. The pumps are by construction single stage, long shaft semi-submersible pumps.

Thanks to its surface treatment, the pump lasts hard and weary use. The JKS and HJKS vortex pumps have no components, to which fibrous matter could be intertwine, neither cramped, blockage sensitive areas.

Materials

HJKS: All the components that are in contact with the fluid are of acid-resistant steel (EN1.4404, AISI 316) and the surface is pickled

JKS: The parts that are in contact with the fluid are of surface treated steel (ball shield, iron phosphating and polyester powder coating) (SFS 5225 SP 40/1-Fe Sa2½Fo, RAL 5003)

JKS ja HJKS:

- Impeller is made of acid-proof steel

- Impeller shaft; stainless steel

- Slide ring Seal: silicon carbide sealing surfaces, body parts acid-resistant steel

- Pump volute, moulded steel plate (JKS) or acid-resistant steel plate (HJKS)

Applications

- Wastewater, sewage and industry pumping liquids and sediments

- Pumping of liquids containing solid particles

- Pumping heavy masses

- Pumping of solid particles containing large particles fines and masses

- In places and processes, where the lumps that the pumped liquid contains don’t need to be shredded and ground

- Rubber lining or with another surface treatment the pump bears hard usage use quite well.

Quality and Documentation

All pumps are test driven at our factory before shipment. Our products confirm to the ISO-9001 quality standard. English documentation is always included with all of our pumps.

Ask for a quote

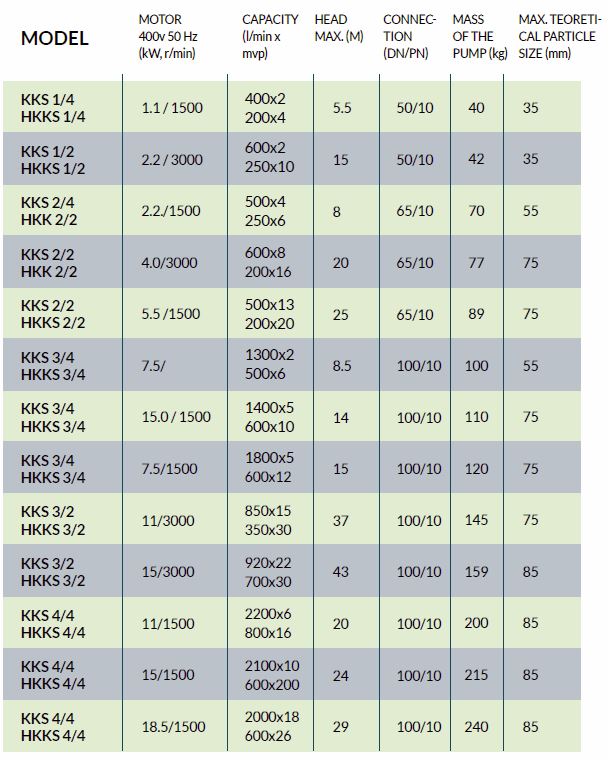

KKS and HKKS Dry-Mounted Vortex Pumps

Sludge pumps for all conditions

Very wide passing JKS and HJKS vortex pumps are suitable for sewage, sediment and wastewater pumps. Rubber lined or with another surface treatment the pumps withstand very hard and abrasive use.

Our dry-mounted and very wide passing vortex pumps are considerable alternative to sewage, sediment and wastewater pumps. They can be used, for example, in industries that handle pumping of difficult masses, stones and sand. KKS and HKKS pumps are well suitable for processes where solid matter is not no need to be shredded and ground.

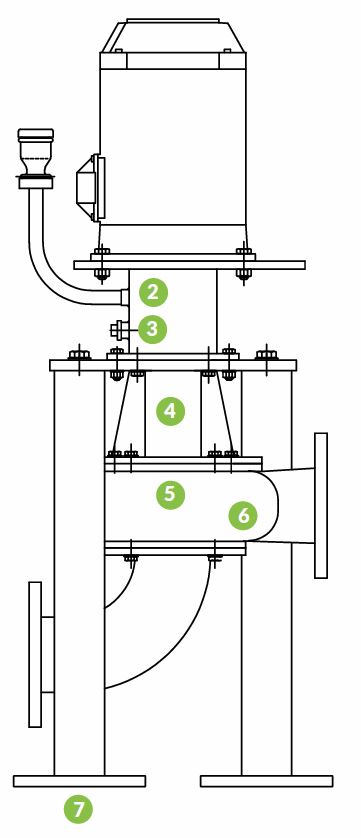

The KKS and HKKS vortex pumps are installed between the piping or for example at the bottom of a tank. The impeller produces a vortex that will get along all the material that can fit in from the inlet.

Materials

HKKS: All the components that are in contact with fluid are of stainless steel (SS 2343, AISI 316), and the surface is pickled.

KKS: The parts that are in contact with fluid are surface treated steel (ball shield, iron phosphating and polyester powder coating) (SFS 5225 SP 40/1 -Fe Sa1 / 2Fo, Ink RAL 5003).

KKS ja HKKS:

- impeller; acid-resistant steel

- impeller shaft; acid-resistant steel

- Slide ring sealing; silicon carbide slider sealing surfaces, body parts acid-resistant steel

- pump volute; moulded steel plate (KKS) or acid-resistant steel plate (HKKS)

Applications

- Wastewater and sewage water pumping

- Moving industrial sediments and liquids

- Pumping of solid lumps, stones and sand

- Pumping heavy masses

- Pumping of solid particles containing large particles fines and masses

- In places and processes, where the lumps that the pumped liquid contains don’t need to be ripped and ground

- Rubber lined or with another surface treatment the pump bears hard abrasive usage use quite well.